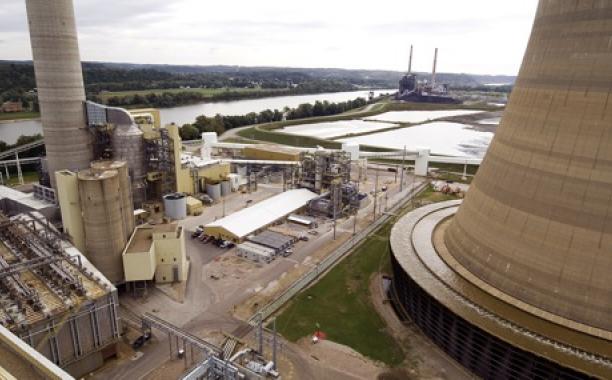

LAST SEPTEMBER, AMERICAN Electric Power’s (AEP’s) Mountaineer power plant in New Haven, W.Va., began doing something no other plant in the world has ever done. It began capturing carbon dioxide (CO2) from a slipstream of exhaust flue gas and pumping it deep underground below the plant for permanent storage in a saline formation. The validation project required retrofitting an advanced chilled ammonia system to the existing coal-fired plant — work performed by members of Local 667 (Charleston, W.Va.) and other building trades.

Initial results of the pilot validation project have been so successful that in December 2009, the Department of Energy awarded a $334 million grant to AEP to bring the project to commercial scale (the total cost to do so is estimated at over $670 million).

0 Comments