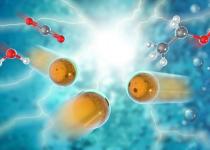

Scientists at Pacific Northwest National Lab have developed a technique that is able to pull carbon dioxide out of the exhaust flue of a power plant or factory for $39 per metric ton, the cheapest cost every reported in a peer-reviewed scientific journal.

To construct a factory to pull carbon dioxide out of the factory exhaust flue with this technique and at this price would cost $750 million.